How does ECO work?

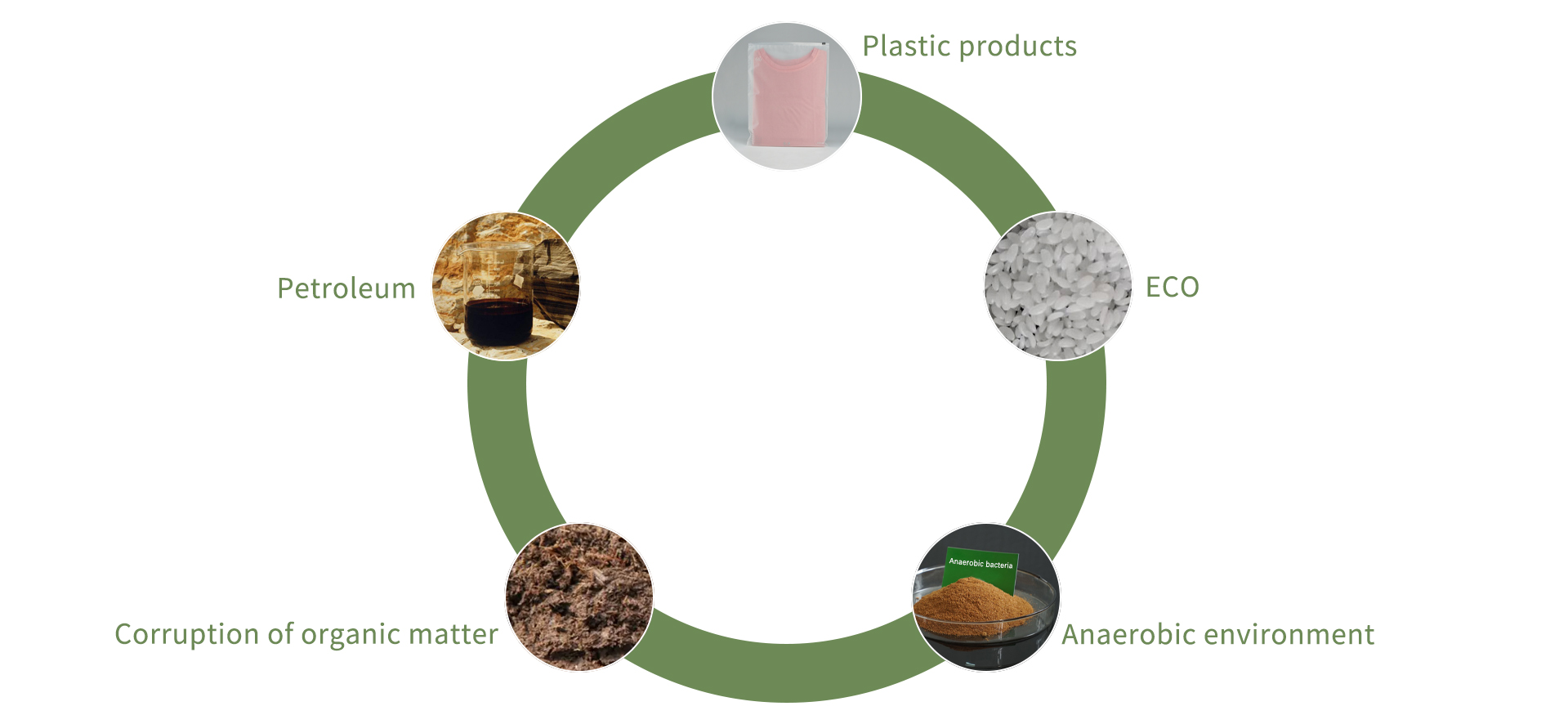

Oil is converted into hydrocarbons by microorganisms from organic decay below the surface, and the remaining organic matter buried in the deep underground undergoes decomposition and complex chemical reactions under temperature and other factor to generate oil. We process petroleum products into various plastic products, and ECO-plasticizer attracts anaerobic bacteria and anaerobic organisms to biochemically reduce plastic products to the original state before the formation of petroleum — organic corrosives, forming a closed loop.

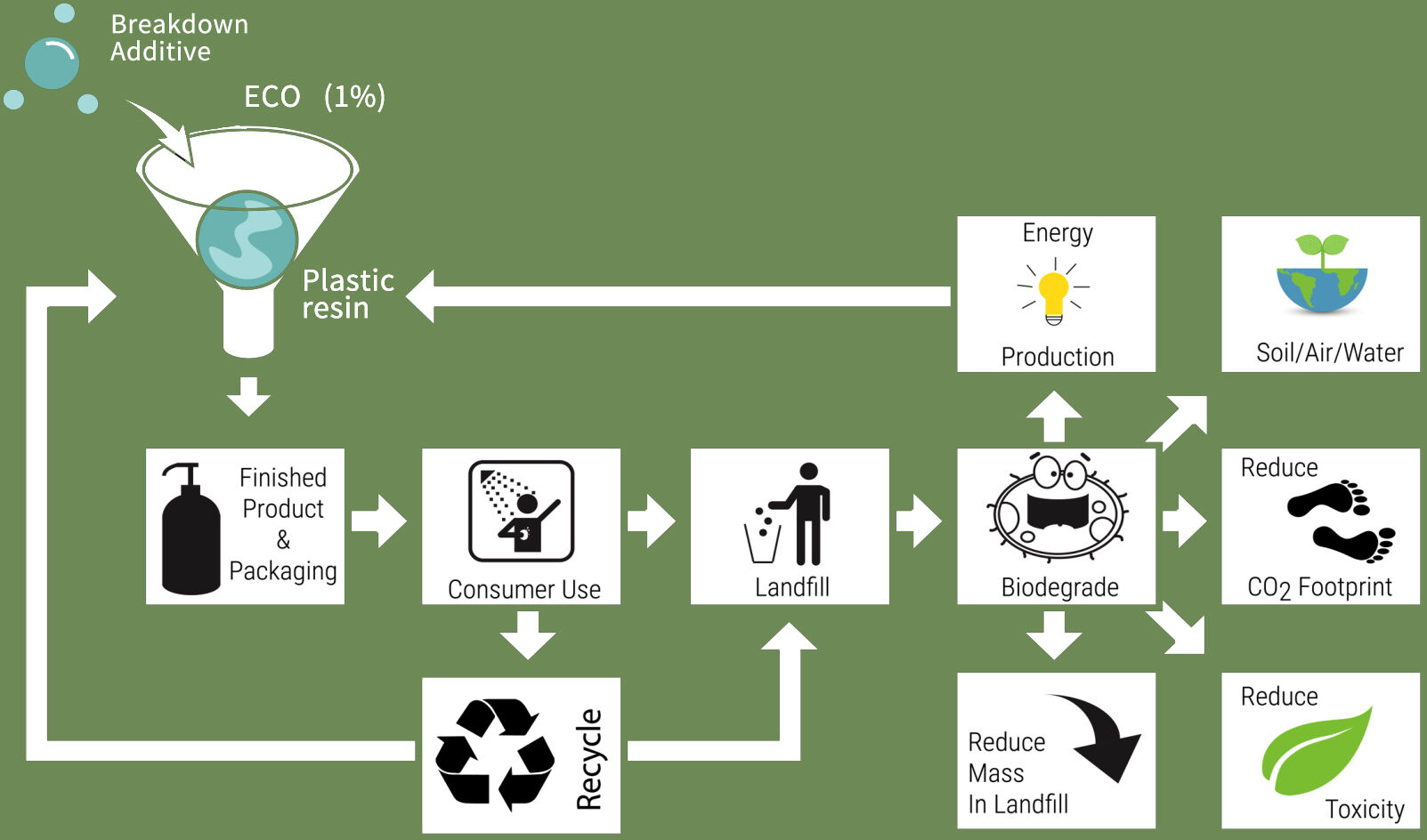

What is ECO? ECO is an organic additive used to accelerate plastic, rubber and PS foam products in landfills (landfills and deep seas) full of active anaerobic organisms The process of making the plastic biodegradable is mixed with the existing plastic material, and then directly blended into the extruder through the hopper. It can also be added and used in proportion online together with a quantitative weighing system. According to different types of plastics and different models, they are all added at a rate of 1%. Application: Any polymer type such as PVC, PET, PP, PO, PE, PC, PS, etc. Compliant with FDA/EU/GB standards and safe with REACH, ISO, ROHS, EFSA, EINECS, CFIA, and can be recycled many times. ECO products are made from traditional plastics injected with anaerobic organic additives, which introduce plastics into the biodegradation stage through chemical activity caused by bacteria, leaving only natural gas and bioenergy at the end.